CASE STUDIES

May 16, 2018

SEALED AIR CHUCK SOLUTION

Situation

A company which produces silicon carbide parts grinds their work piece at the inner and outer diameters. Silicon carbide is a very aggressive material and when grinding, it creates a lot of metal powder that accumulates in the chuck and also sends mist in the air. Using a competitor's open air chucks, the operation frequently stopped abruptly due to dirt in the chuck. The customer often had to dismount the chuck for clean-up and repairs, which created many delays. The organization approached PML-PAL to provide a more sustainable solution.

Solution

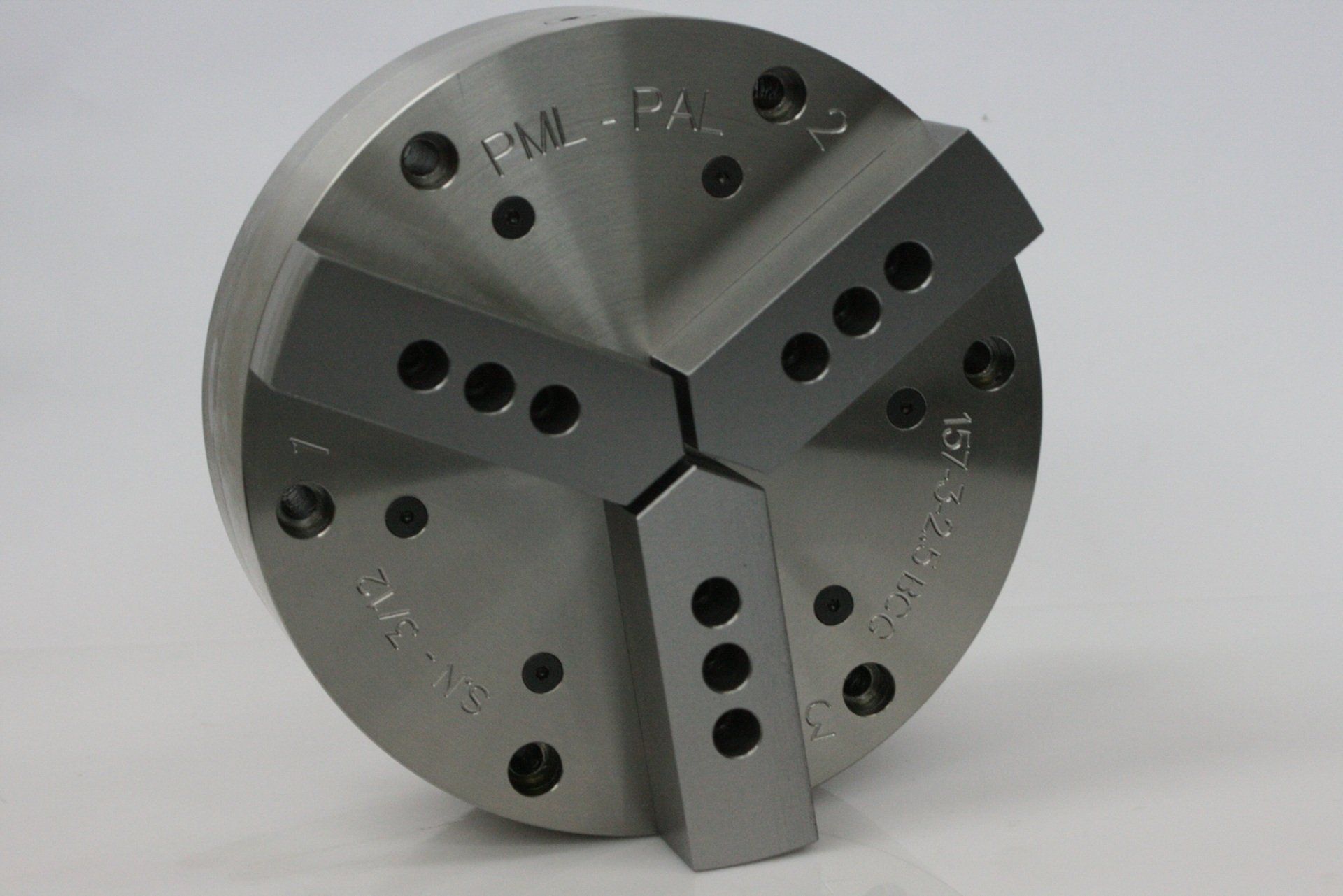

PML-PAL engineering offered a stock item, a special sealed chuck model 157-3-2.5 BCG, which is 157mm diameter, three sliding jaws to clamp the concerned work piece.

This chuck has a sealing mechanism that does not allow any metal dust or swarf to penetrate it.

Results

Since the customer installed the PML-PAL sealed chuck, they have been running nonstop and have never stopped the operation for dust clean up. Productivity has

increased substantially with the absence of unpredictable work stoppages