ABOUT

PML-PAL

is a brand of high precision air (pneumatic) chucks for various CNC machining applications. PML-PAL high precision pneumatic air chucks, fixtures and accessories are designed, manufactured and marketed by Henri Azaria PAL Ltd., an ISO 9001: 2015 certified family-owned Israeli machining company in business since 1969. We also make accessories for high precision pneumatic chucks and multiple workholding fixtures for higher productivity and mass production. As subcontractors, we produce customized high precision workpieces up to 0.001 mm.

About PML-PAL brand

In 1993, the firm purchased the PML line of high precision pneumatic chucks for which it continuously provides R&D, worldwide marketing, and support services.As opposed to ordinary attachments to metal working machines, PML-PAL chucks are auxiliary equipment designed to solve technical gripping challenges.

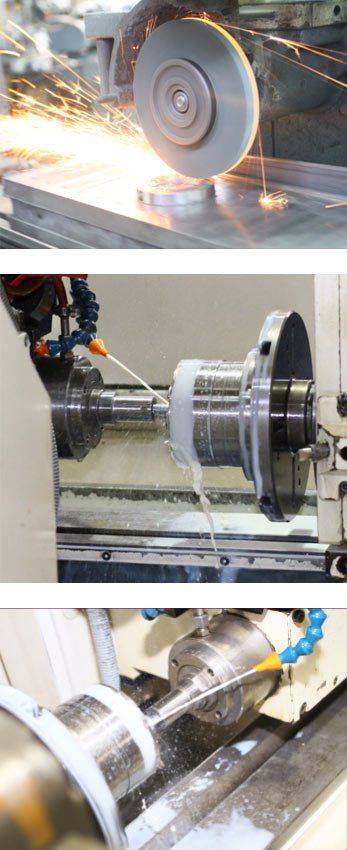

The chucks are mostly helpful while gripping non-standard shapes, soft materials, and complex precise work pieces.The chucks are also used for second operation of mass production and fine finishing cut-operations.

They are suitable for high speed turning, precise milling, and high precision grinding.There are specific models for rotary tables, measuring and quality control, and many more specialized applications.The company also manufactures hermetically-sealed diaphragm chucks that have a clamping repeatability of 0.0006 mm or 0.000024” and rotating capability of 15,000 RPM.

Custom-made Solutions

The company is highly adaptable. We pride ourselves on our creativity, flexibility and ability to solve most customer challenges and deliver timely solutions. We provide our clients with rapid research and development (R&D), quick manufacturing of custom parts, and design services.

We provide comprehensive technical support services, from assistance and consultation prior to purchase, to ongoing training, recondition and repair services. The company is fully-equipped to produce both large and small quantities, including a single chuck, flange or fixture. The finished products are thermally treated then coated or painted according to client specifications.

These jobs are performed by technically approved subcontractors, licensed by the Israeli Standard Institute and/or Israeli high-tech industries.

PML-PAL

is a brand of high precision air (pneumatic) chucks for various CNC machining applications. PML-PAL high precision pneumatic air chucks, fixtures and accessories are designed, manufactured and marketed by Henri Azaria PAL Ltd., an ISO 9001: 2015 certified family-owned Israeli machining company in business since 1969. We also make accessories for high precision pneumatic chucks and multiple workholding fixtures for higher productivity and mass production. As subcontractors, we produce customized high precision workpieces up to 0.001 mm.

About PML-PAL brand

In 1993, the firm purchased the PML line of high precision pneumatic chucks for which it continuously provides R&D, worldwide marketing, and support services.As opposed to ordinary attachments to metal working machines, PML-PAL chucks are auxiliary equipment designed to solve technical gripping challenges.

The chucks are mostly helpful while gripping non-standard shapes, soft materials, and complex precise work pieces.The chucks are also used for second operation of mass production and fine finishing cut-operations.

They are suitable for high speed turning, precise milling, and high precision grinding.There are specific models for rotary tables, measuring and quality control, and many more specialized applications.The company also manufactures hermetically-sealed diaphragm chucks that have a clamping repeatability of 0.0006 mm or 0.000024” and rotating capability of 15,000 RPM.

Custom-made Solutions

The company is highly adaptable. We pride ourselves on our creativity, flexibility and ability to solve most customer challenges and deliver timely solutions. We provide our clients with rapid research and development (R&D), quick manufacturing of custom parts, and design services.

We provide comprehensive technical support services, from assistance and consultation prior to purchase, to ongoing training, recondition and repair services. The company is fully-equipped to produce both large and small quantities, including a single chuck, flange or fixture. The finished products are thermally treated then coated or painted according to client specifications.

These jobs are performed by technically approved subcontractors, licensed by the Israeli Standard Institute and/or Israeli high-tech industries.

CONTACT US

Contact Us

תודה רבה, הטופס נשלח בהצלחה

אירעה שגיאה בהזנת הפרטים, אנא נסו שנית