SPECIAL CHUCKS

June 05, 2018

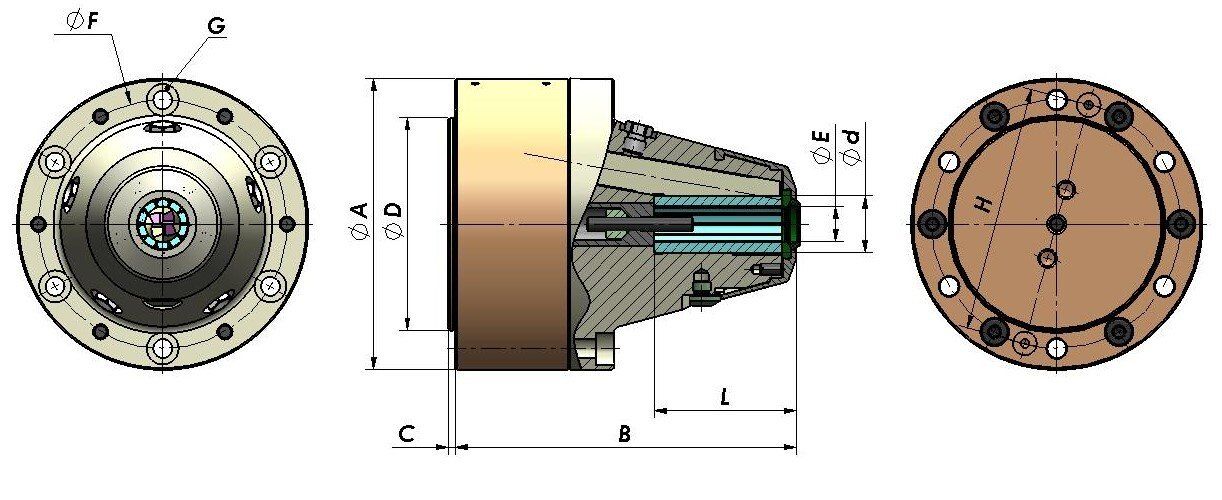

PRECISION CONICAL AIR CHUCK

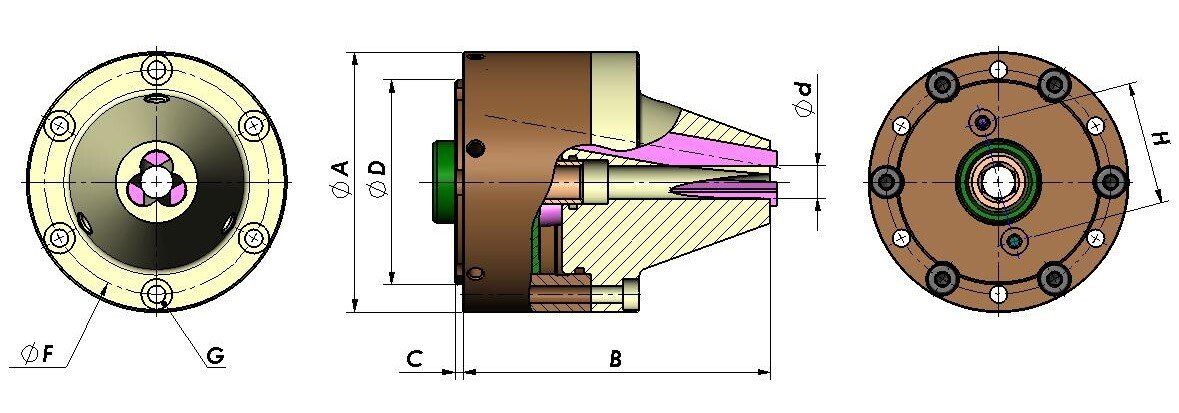

The conical precision air chuck is a unique one. It is designed to clamp cutting tools like end-mills, drills, reamers, threading tools / taps in a 5 axes CNC grinding machine.

The conical shape allows easy access to the grinding wheel tool. The conical chuck is operated by either integrated air piston or draw bar connected to a back air cylinder.

The need for this chuck arises when a customer approach PML-PAL with a request to have a super high precision chuck with conical front shape which allows the grinding wheel to approach as close as possible to the chuck's face without hitting it and grind the tool as low as possible (in relation to its cutting edge).

Advantages of conical chuck:

In the chuck there is a stopper that controls how deep the tool goes in. Each chuck model can clamp four different workpiece diameters (3, 4, 5, and 6mm) by using accurate, quick change insert. Alternatively, in order to cover the whole diameter range, there is a need to use four different chucks.

There are two types of chuck:

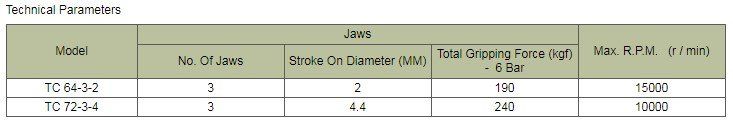

Three jaws chuck – the usage is precision and tight clamping in high RPM (up to 20,000). It can be operated by air or back drawbar pulling.

Five jaws chuck – the usage is precision tool clamping in CNC grinder. It's advantages are using one chuck type to hold several diameters. The repeatability is within a few microns . It can be operated by air or back drawbar pulling.

This chuck is extremely accurate. Repeatability is 0.0005mm or 0.00002".

This is a three jaw tool clamping high precision chuck

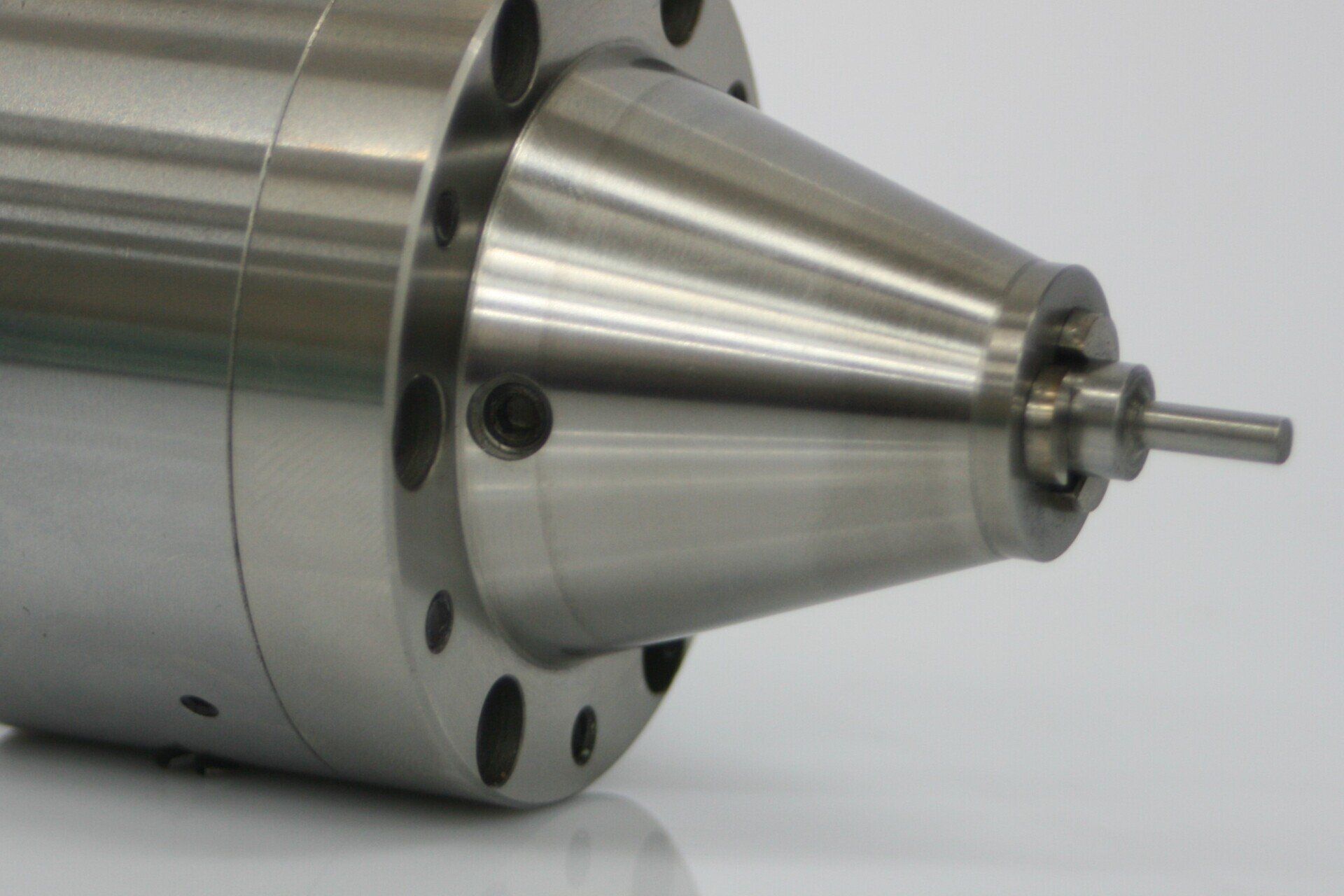

Close up on the conical air chuck

This is a five jaw tool clamping high precision chuck

CONTACT US

Contact Us

תודה רבה, הטופס נשלח בהצלחה

אירעה שגיאה בהזנת הפרטים, אנא נסו שנית