UNIQUE SOLUTIONS

June 11, 2018

CHUCK BODY MAKING PROCESS

How does a chuck get made using another high precision air chuck?

This unique case study illustrates a real situation in a machining set up where a large workpiece is machined efficiently: fast with minimum clamps. We will demonstrate how a 350mm chuck body is made using another 200mm high precision air chuck to clamp it 200-3-2.5 ST while it is being milled. The below large workpiece will be transformed into a chuck body using the fewest clamps possible and in the shortest time. The photos below illustrate the process along with the clamping system.

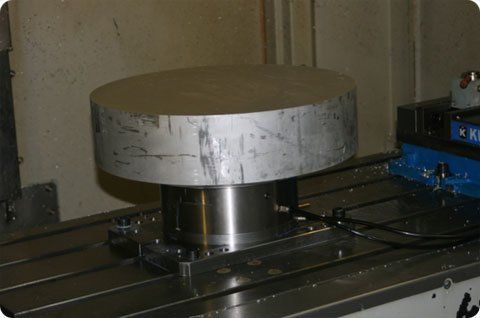

1. Large raw material waiting on the floor to be transformed into a precision air chuck bod

2. The workpiece is prepared for first operation.

The bottom is milled in order to be clamped by an air chuck from the inner diameter.

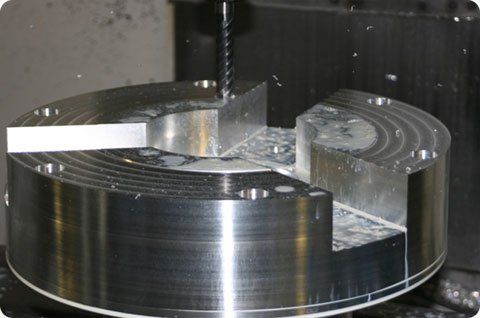

3. 200mm Stationary Precision Air Chuck with milled jaws in order to fit the above workpiece.

As noticed we are going to clamp the workpiece from the inner diameter.

4. The workpiece is easily clamped on the air chuck. The gripping force is 2800kN.

5. The workpiece is milled without any obstacles around it.

6. The precision air chuck on the bottom creates obstacle free environment above and

around the workpiece.

7. This is the end of the first operation. The workpiece is done on the upper side and

outer diameter.

8. The workpiece is dismounted effortlessly and put back on the floor.

9. The next workpiece will be mounted on the chuck the same way. No need to center it

again. The accuracy is 0.002 mm.

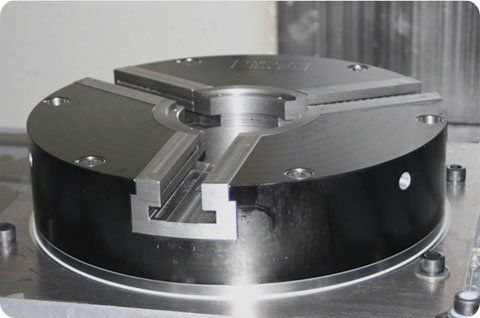

10. Before second operation, we prepare the clamping system appropriately. The chuck

stays mounted on the machine. We remove the first operation jaws, and install another

set of jaws. Then mill them to fit the other side of the chuck body for second operation as

illustrated below. Again, clamping from the inner diameter.

11. The chuck body is then mounted instantly and ready to be machined.

12. Almost done…..

13. As noticed there are no obstacles around the chuck for smooth operation.

14. Now the second operation is done.

15. The operator dismounts the chuck body.

16. The chuck body is back on the floor.

17. As noticed, the chuck body is made from Aluminum material that goes through hard

anodizing process coated black.

We have decided to use Aluminum body in order to reduce substantial amount of load

from the overall chuck weight. The aluminum chuck weight is substantially lighter than

equivalent stainless steel chuck.

18. We used iron cast inserts and other hardened materials for the working parts

19. This is the final product from different angles.

20. Bottom view

CONTACT US

Contact Us

תודה רבה, הטופס נשלח בהצלחה

אירעה שגיאה בהזנת הפרטים, אנא נסו שנית