AIR CHUCKS

Advantages of high precision air chucks

Up to 0.0005mm or 0.00002" chucking repeatability

Accurate thin wall turning and grinding

Integral and adjustable pneumatic power

Quick acting operation

High speed performance

Compact structure

Minimum weight and volume

Easy installation

Fits pneumatic and electric systems

Foolproof safety

Four way Air Feed control valve

CNC adaptable

High reliability

ID and OD clamping with same chuck model

Catalog Contents:

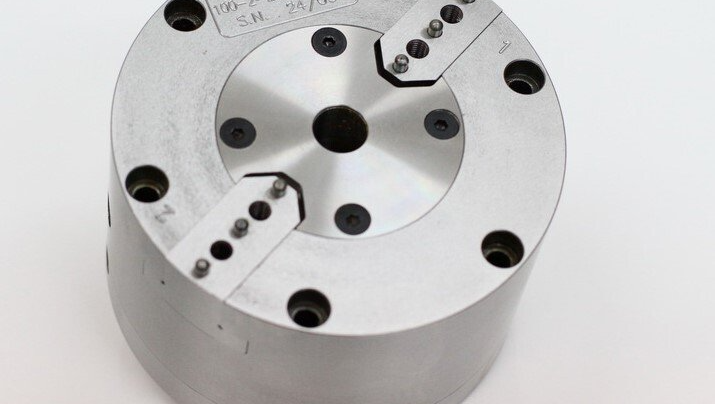

Turning chuck

Grinding chuck

Milling/Stationary chuck

Stationary with through hole

Diaphragm chuck

Jaws

Air Feed Tube

High speed precision air chucks are designed to spin at up to 6000 rpm. The high speed air chuck has a large back...

Diaphragm chuck is a sealed chuck used for super high precision work.It provides almost absolute...

Pneumatic (air) miniature grippers are used for material handling and robots as well. Body material:...

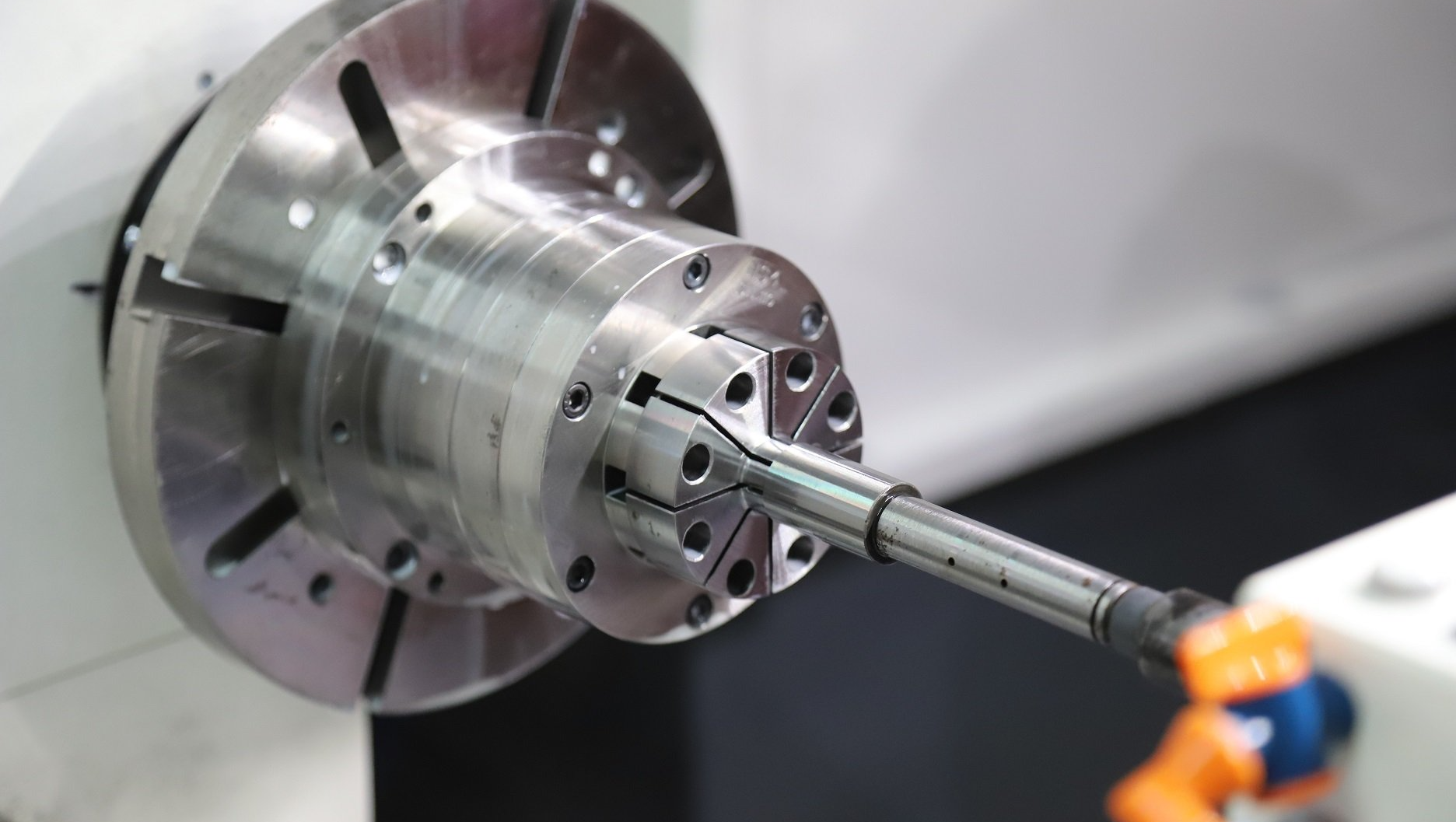

High precision turning or rotating air chucks are designed to be mounted on any CNC turning and conventional...

High precision grinding air rotating chucks are sealed. The pneumatic chucks are designed to operate on CN...

Stationary precision pneumatic air chuck is designed to clamp round and non-conventional shape work piece on...

Stationary precision air chucks with through hole are designed to clamp non-conventional shape work piece on...

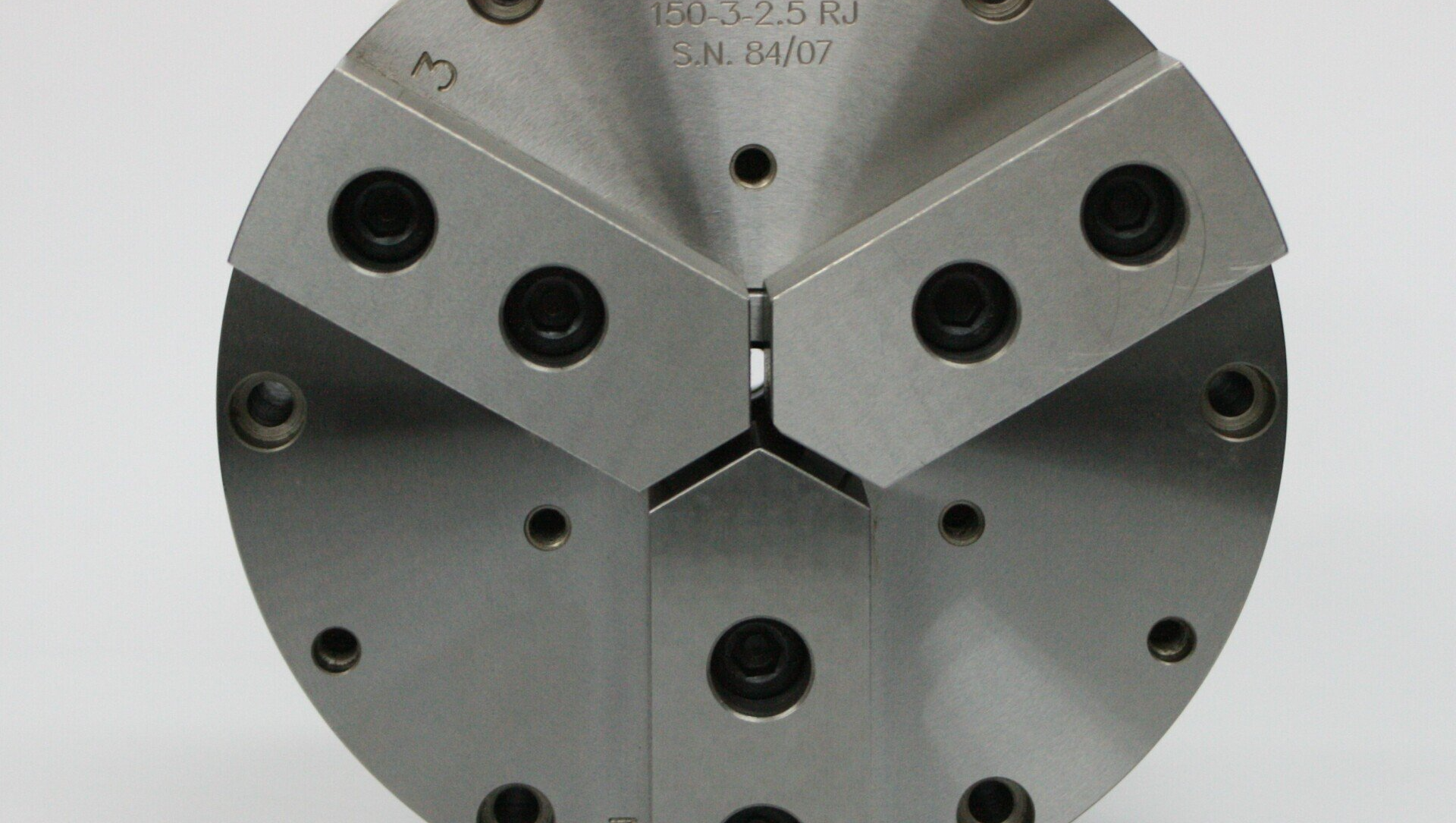

This is a Sealed Round Jaws (RJ) Super High Precision Chuck. The round jaws technology provides super high...

Rotary Table high precision air chuck uniquely designed to be mounted on 4th and 5th axes, index table - verticall...