CASE STUDIES

May 19, 2018

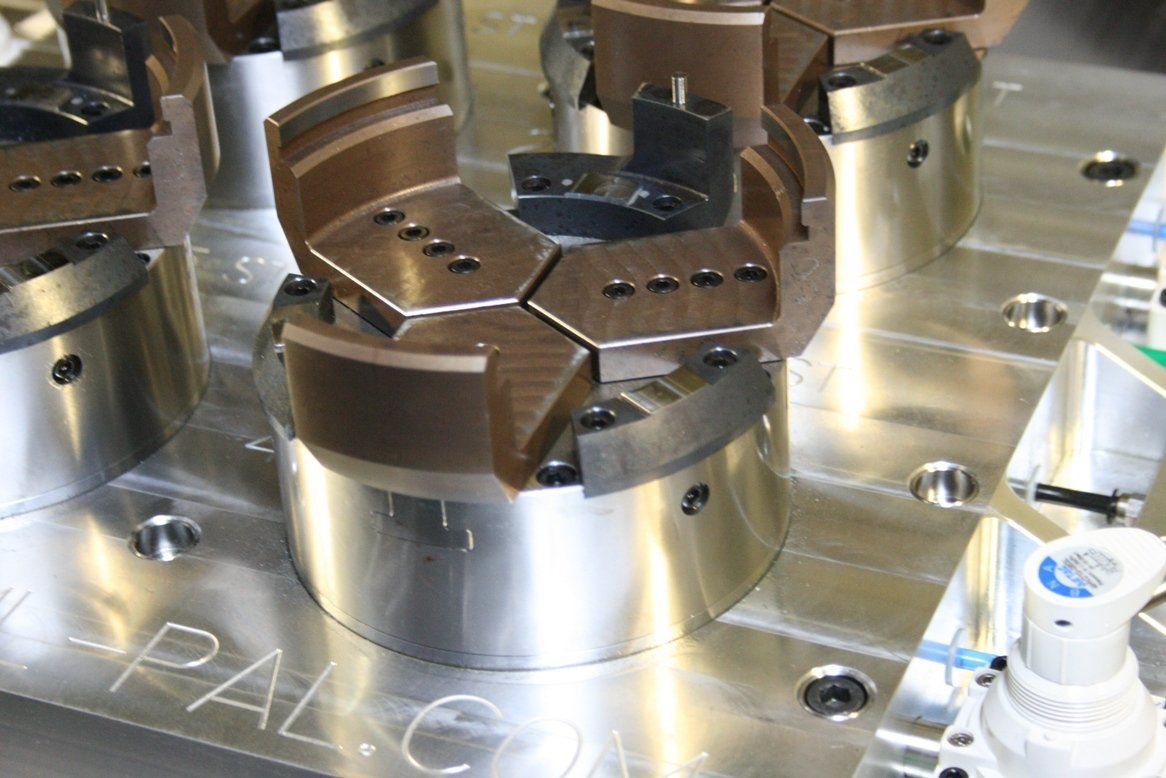

CUSTOM FIXTURE STATIONARY

Situation

An automotive customer contacted PML-PAL Engineering revealing that he currently manufactures certain part running three milling operations on three machines making one part at the time. Total operating time for each work-piece was around 12 minutes including manual load/unload and manual set up on each machine. The customer asked to help to streamline his production.

Solution

PML-PAL worked closely with the customer to come up with an agreeable solution given a few working environment constraints. We designed an Aluminum fixture to

hold four stationary precision air chucks model 150-3-2.5 ST. Each chuck includes three custom jaws, height stoppers, and an orientation pin. Each chuck has its own

operating air valve for a quick clamping and release. Each chuck has a safety air valve as well in case of air supply interruption (more information is available @

Results

The customer effortlessly installed the fixture on his CNC machining center. Now the machine runs four work pieces simultaneously. It is easy to load, orient, and unload

the parts on each chuck. All operations are done on one machine. Bottom line….the cycle time is now less than 8 minutes for four (4) work pieces down from 48 minutes,

savings of over 80%.