AIR CHUCKS

June 27, 2022

TURNING AIR CHUCK

High precision turning or rotating air chucks are designed to be mounted on any CNC turning and conventional machine. The speed for rotating precision air chuck is up to 6000 rpm. Controlled clamping force enables clamping of thin-walled and other gentle parts with no distortion. Most models come with coolant or air passage through the center of the chuck.

It is very simple to mount the air chuck on the CNC lathe machine.

An experienced operator may do it in several minutes.

Simple loading and unloading. Most chucks come with 2, 3, or 4 jaws as standard.

Most standard models are available in inventory.

The pneumatic chuck accuracy is 0.002mm or 0.0001".

Chuck size ranges from 50mm to 350mm or 2" to 14".

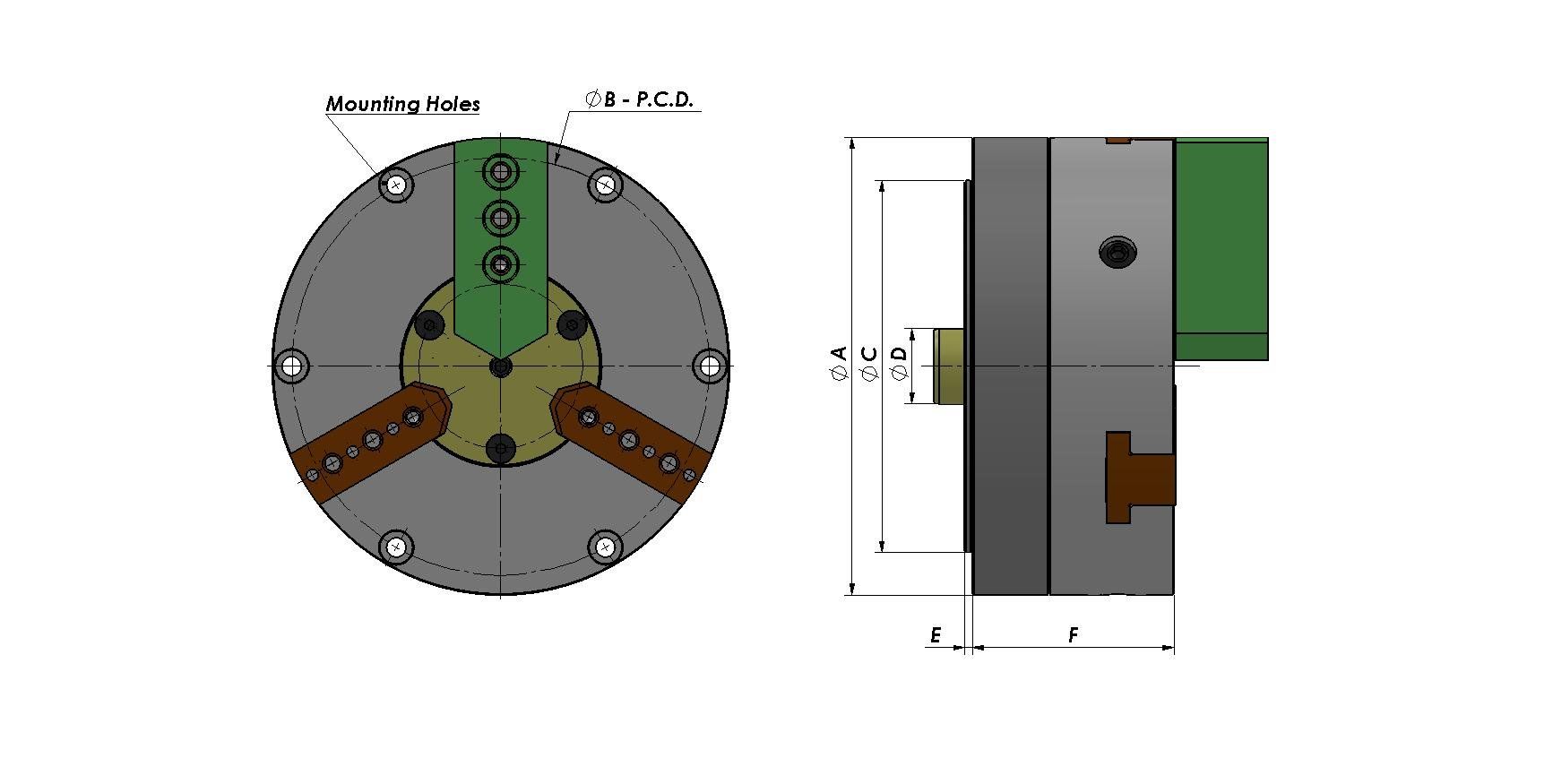

Mechanical Parameters in mm

| Model | A | B P.C.D. | C | D | E | F |

|---|---|---|---|---|---|---|

| 50-3-2 BC | 51 | 42.3 | 32 | 20.4 | 1.8 | 40 |

| 50-3-2 NBC | 51 | 42.3 | 32 | 23 | 1.8 | 40 |

| 64-3-2 BC | 63.5 | 52 | 50 | 20.6 | 2 | 42 |

| 82-3-2 BC | 82 | 70 | 60 | 20.6 | 2 | 50 |

| 83-3-2.5 NBC | 83 | 70 | 60 | 20.6 | 2 | 50 |

| 100-2-2.5 BC | 100 | 88.9 | 82.55 | 21 | 2.2 | 55.7 |

| 100-2-2.5 NBC | 100 | 88.9 | 82.55 | 21 | 2.2 | 55.7 |

| 100-3-2.5 BC | 100 | 88.9 | 82.55 | 21 | 2.2 | 55.2 |

| 100-3-2.5 NBC | 100 | 88.9 | 82.55 | 21 | 2.2 | 55.2 |

| 100-4-2.5 BC | 100 | 88.9 | 82.55 | 21 | 2.2 | 55.2 |

| 125-3-2.5 BC | 125 | 114.3 | 101.6 | 21 | 2.2 | 55 |

| 125-3-2.5 NBC | 125 | 114.3 | 101.6 | 21 | 2.2 | 55 |

| 150-3-2.5 BC | 150 | 135.75 | 125 | 21 | 2.2 | 55 |

| 150-3-2.5 NBC | 150 | 135.75 | 125 | 21 | 2.2 | 55 |

| 150-3-2.5 BC-S | 150 | 135.75 | 125 | 21 | 2.2 | 60 |

| 150-3-2.5 NBC-S | 150 | 135.75 | 125 | 21 | 2.2 | 60 |

| 150-4-2.5 BC | 150 | 135.75 | 125 | 21 | 2.2 | 57 |

| 150-4-2.5 NBC | 150 | 135.75 | 125 | 21 | 2.2 | 57 |

| 200-3-2.5 BC | 203.2 | 183 | 167.6 | 25 | 6.8 | 80.5 |

| 200-3-2.5 NBC | 203.2 | 183 | 167.6 | 25 | 6.8 | 80.5 |

| 250-3-2.5 BC | 254 | 233.7 | 215.8 | 25 | 7.2 | 73.5 |

| 250-3-2.5 NBC | 254 | 233.7 | 215.8 | 25 | 7.2 | 73.5 |

Technical parameters

| Model | Number of Jaws | Stroke on Diameter (mm) | Maximum R.P.M. (r/min) | Total Gripping Force (kgf) - 6 Bar |

|---|---|---|---|---|

| 50-3-2 BC | 3 | 2 | 6000 | 86* |

| 50-3-2 NBC | 3 | 2 | 6000 | 86* |

| 64-3-2 BC | 2,3 | 2/1 | 3500 | 83* |

| 82-3-2.5 BC | 2,3 | 2.5 | 3000 | 184* |

| 83-3-2.5 NBC | 2,3 | 2.5 | 3500 | 263* |

| 100-2-2.5 BC | 2 | 2.5 | 4000 | 485* |

| 100-2-2.5 NBC | 2 | 2.5 | 4000 | 485* |

| 100-3-2.5 BC | 3 | 2.5 | 3500 | 485* |

| 100-3-2.5 NBC | 3 | 2.5 | 3500 | 485* |

| 100-4-2.5 NBC | 4 | 2.5 | 3000 | 430* |

| 100-4-2.5 BC | 4 | 2.5 | 3000 | 430* |

| 125-3-2.5 BC | 2,3,4 | 2.5/1.2 | 4000 | 970* |

| 125-3-2.5 NBC | 2,3,4 | 2.5/1.2 | 4000 | 970* |

| 150-3-2.5 BC | 2,3,4 | 2.5/1.2 | 4000 | 1240** |

| 150-3-2.5 NBC | 2,3,4 | 2.5/1.2 | 4000 | 1240** |

| 150-3-2.5 BC-S | 2,3 | 2.5/1.2 | 4500 | 1770** |

| 150-3-2.5 NBC-S | 2,3 | 2.5/1.2 | 4500 | 1770** |

| 150-4-2.5 NBC | 4 | 2.5/1.2 | 4000 | 1500** |

| 150-4-2.5 BC | 4 | 2.5/1.2 | 4000 | 1500** |

| 200-3-2.5 BC | 3 | 2.5/1.2 | 2000 | 2800*** |

| 200-3-2.5 NBC | 3 | 2.5/1.2 | 2000 | 2800*** |

| 250-3-2.5 BC | 3 | 2.5/1.2 | 2000 | 3150*** |

| 250-3-2.5 NBC | 3 | 2.5/1.2 | 2000 | 3150*** |

*Calculated with top steel jaws H=16mm

**Calculated with top steel jaws H=25mm

***Calculated with top steel jaws H=50mm

200-4-2.5 BC model,

200mm or 8 inch, 4 jaw high precision air chuck

200-3-2.5 NBC model, 200mm or 8 inch, 3 jaw high precision air chuck

50-3-2 BC model, 50mm or 2 inch, 3 jaw high precision turning air chuck

64-3-2 BC model, 64mm or 2.5", 3 jaw high precision turning air chuck

The above photo shows the machine back side with the air feed tube (AFT) mounted.

PML-PAL precision air chuck is installed on a Mazak Ravema at a customer site in Sweden.